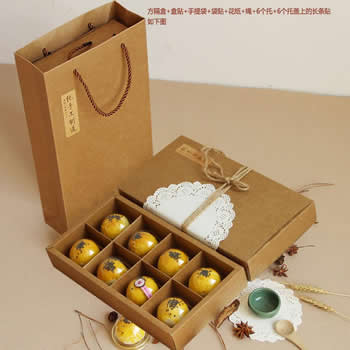

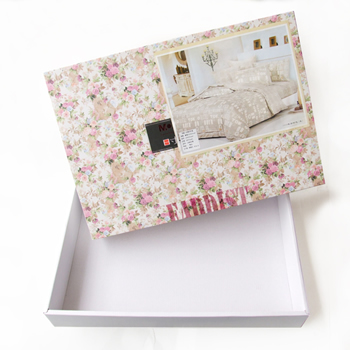

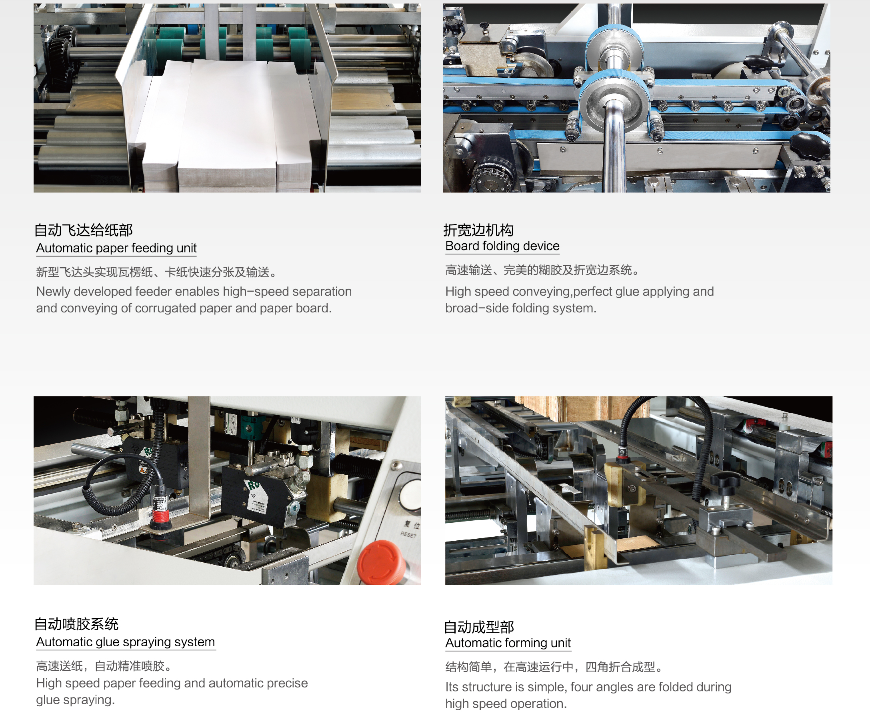

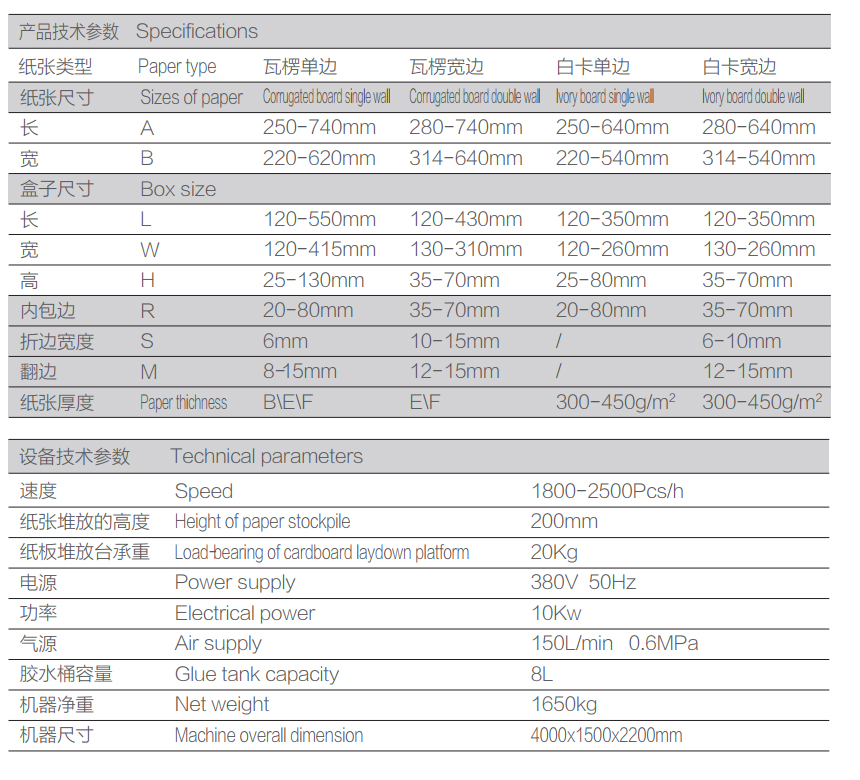

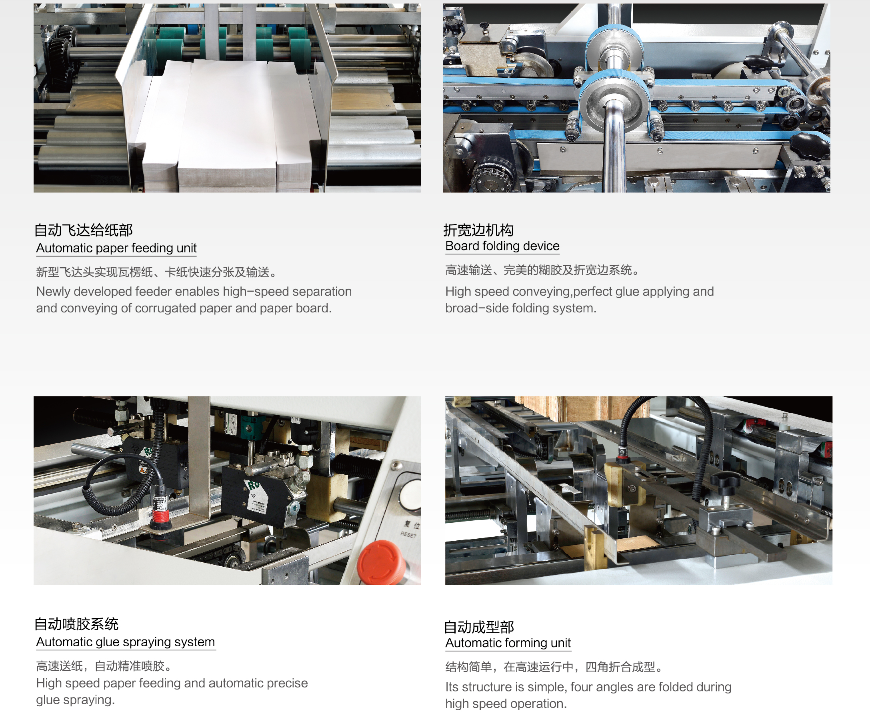

本機(jī)采用伺服控制系統(tǒng)、可編程PLC程序控制系統(tǒng)、光電跟蹤、瑞士樂(lè)百得熱熔膠噴膠系統(tǒng)、觸摸屏人機(jī)界面控制系統(tǒng),集機(jī)電氣為一體實(shí)現(xiàn)自動(dòng)送紙、噴膠、折邊及成型動(dòng)作一次性完成。主要適用于300-450白卡紙、牛皮紙、B/E/F瓦楞紙等包裝材質(zhì)的紙盒生產(chǎn),廣泛應(yīng)用于食品、化妝品、服裝、文具、玩具、水果、酒盒、日用品、保健品等天地蓋包裝紙盒需求。

設(shè)備特點(diǎn):

注:

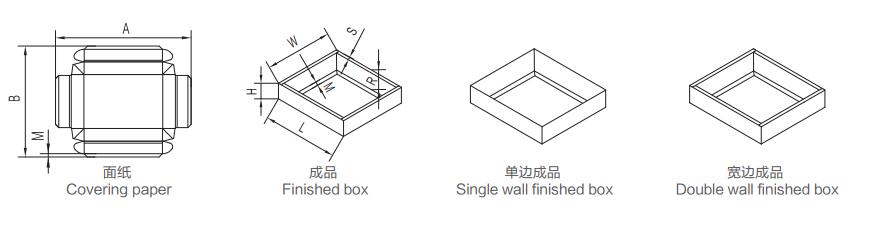

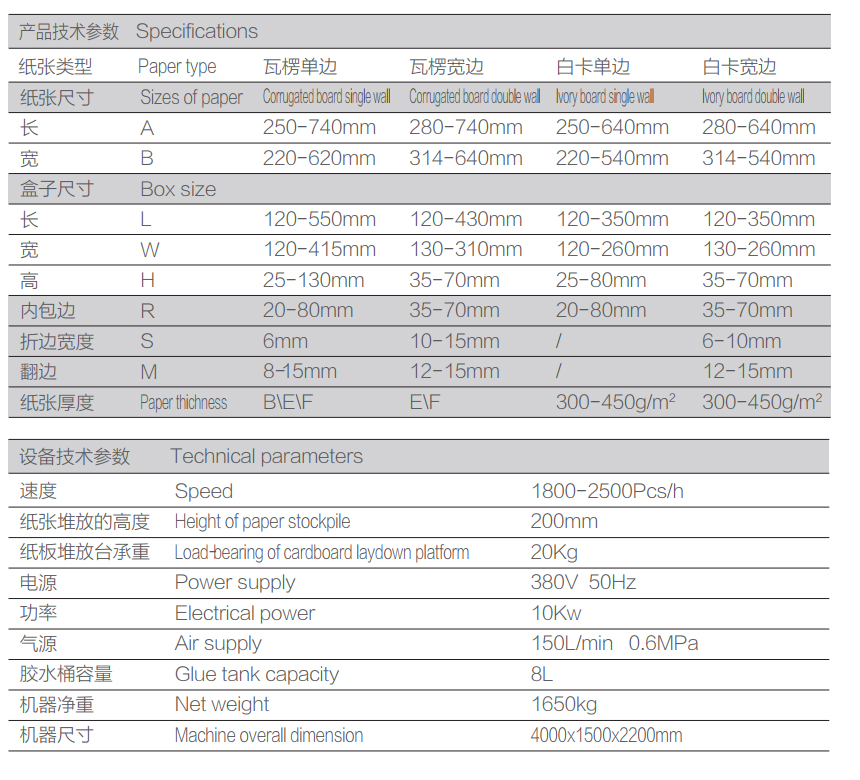

1. 小盒子長(zhǎng)度L=Hx2+20mm+Mx2,成型導(dǎo)軌里面紙板寬向展開(kāi)尺寸≤500mm;

2. 本司不提供空氣壓縮機(jī);

3. 影響機(jī)器速度的幾個(gè)因素:原材料,膠水和操作者的熟練程度;

4. 由于產(chǎn)品設(shè)計(jì)不斷創(chuàng)新,以上數(shù)據(jù)僅供參考;如有變更恕不另行通知。

Note:

1. The length of the small box is L=Hx2+20mm+M×2, and the width of the cardboard in the forming guider is ≤500mm;

2. The company does not provide air compressors;

3. Several factors that affect the speed of the machine: raw materials, glue and operator proficiency;

4. Due to continuous innovation in product design, the above data is for reference only; subject to change without notice